Product Description:

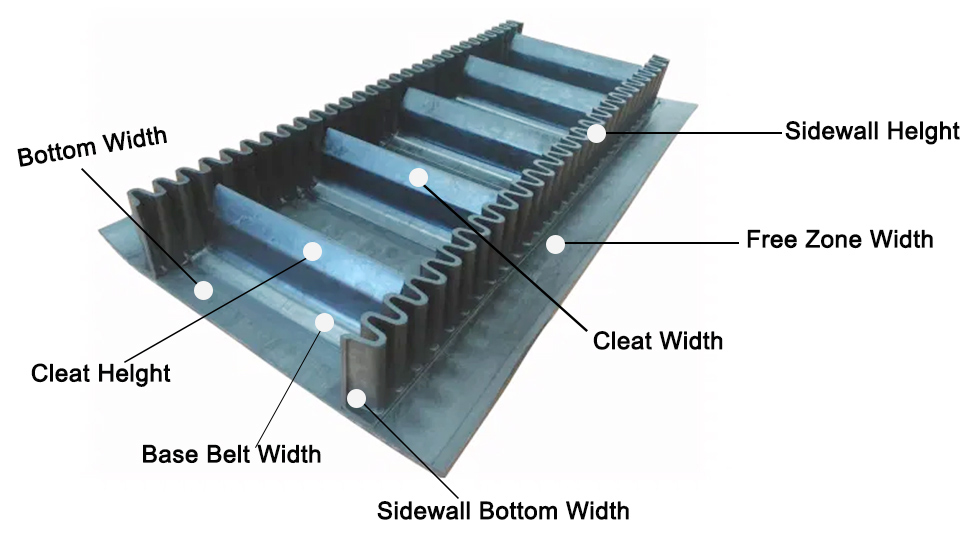

Our sidewall conveyor belt can realize the high-volume and steep-angle delivery of materials in limited space. It is composed of three parts, namely base belt, sidewall and cleat. The sidewall with its unique design can keep materials from sliding down. To facilitate bypassing the roller, the sidewall is corrugated and can endure high pressure and repeated bending. The cleat, with a large carrying capacity and dip angle, is the main part of conveying materials. In order to achieve large-angel delivery, T-style and TC-style are adopted. The sidewall and cleat are connected to the base belt through secondary vulcanization, showing high joint strength. The reinforced inner wall, combining flexibility and strength, can effectively avoid tearing. Our sidewall conveyor belts are mainly applied to convey granular or liquid material. The conveyor belt with sidewalls possesses many features such as heat resistance, abrasion resistance, fire prevention, low-temperature resistance, oil resistance, skid resistance and alkali resistance. Before leaving our sidewall conveyor belt factory, our products are tested for tensile strength, anti-abrasion and adhesion, thus meeting the requirements of clients.

Product Applications:

The sidewall conveyor belt of our company, one of corrugated sidewall conveyor belt manufacturers, can transport various bulk materials. It has been widely applied to metallurgy, electricity, coal, the chemical industry, grain, port and machinery.

Product Features and Advantages:

Low elongation

Long using period

Fire resistant

Able to endure low and high temperatures

Unique design

Oil-proof

Resistant to alkali

Simple structure

High delivery capacity

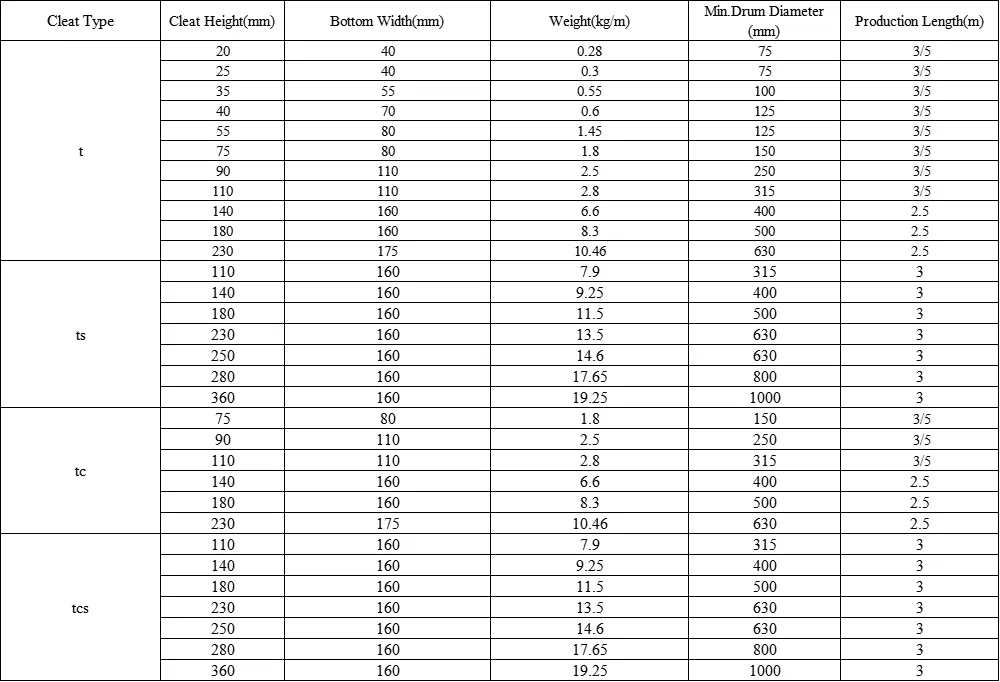

Product Specification: