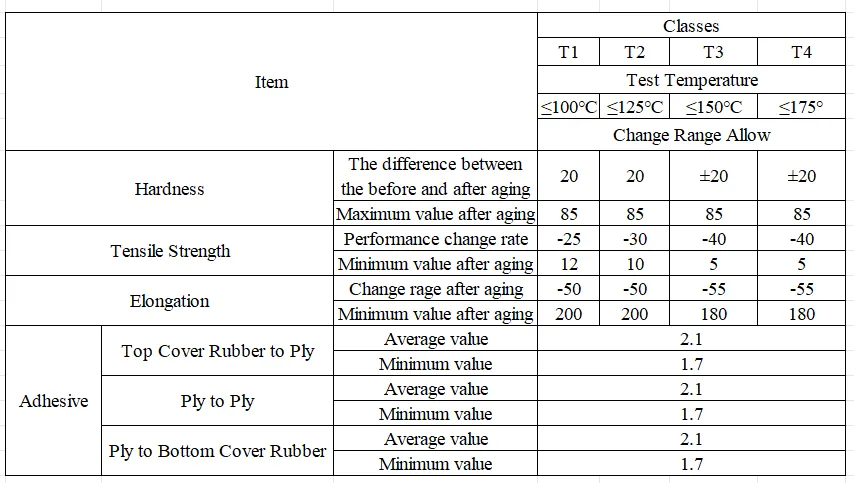

Product Description:

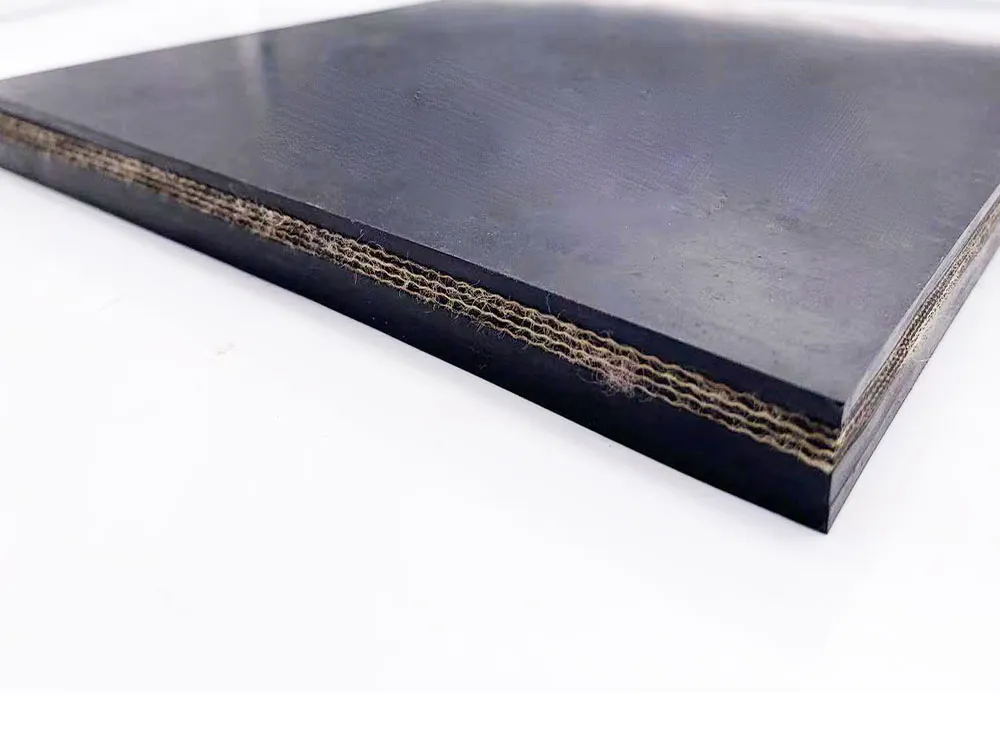

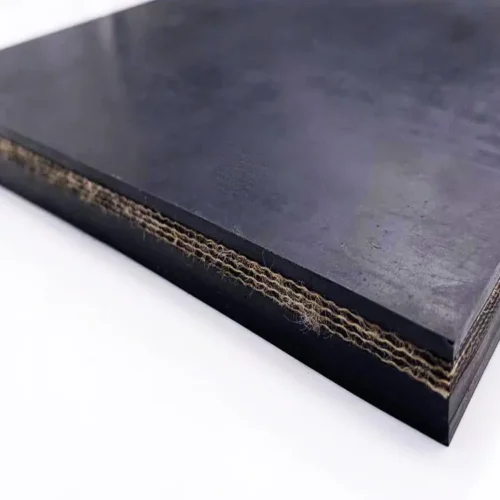

Heat resistant conveyor belts are composed of multi-layer polyester cloth with the heat-resistant rubber cover. Through high-temperature vulcanization, the cloth is bonded to form belts. For the working surface, the top rubber touches hot material directly. The heat resistance conveyor belt with general purposes cracks and hardens easily in such conditions. Our company, the best heat resistant conveyor belt manufacturer, has four top rubber formulations to keep belts from cracking and hardening owing to heating, abrasion and ageing. Ethylene Propylene Diene Monomer (EPDM) has been widely demonstrated to be a super high-quality material for improving the heating-resistance property of belts. This high temperature conveyor belt is appropriate for delivering hot coke, cement, cinder and hot casting. The belts are classified into four categories. The first type is T1, which can endure less than 100℃ of testing temperature. Its maximum operating temperature in the short term is 150℃. The second type is T2, which can endure less than 125℃ of testing temperature. Its maximum operating temperature in the short term is 170℃. The third type is T3, which can endure less than 150℃ of testing temperature. Its maximum operating temperature in the short term is 200℃. The fourth type is T4, which can endure less than 175℃ of testing temperature. Its maximum operating temperature in the short term is 400℃.

Product Applications:

Our heat resistant conveyor belts are mainly appropriate for conveying material with particularly high temperatures, such as burnt-out ore and cement clinker in metallurgy, iron and steel and casting industries.

Product Features and Benefits:

Lightweight belt body

Long usage period

Excellent heat-resistant performance

Abrasion resistant

Super durability

Ozone resistant

Anti-weathering

Chemical corrosion resistance

Product Specification: