Any plant or maker will always try to make things faster, directly affecting their profitability and reliability. A conveyor belt is an essential part of production capacity. Using a conveyor belt can reduce the amount of work that needs to be done by hand and speed up delivery. Consequently, suppliers and business owners today use high-quality conveyor belts that last a long time. Thus, the subject “PVC VS Rubber Conveyor Belt” is essential.

People use both PVC and rubber conveyor belts for many different reasons. The place where they are used is what makes them unique. But there are also some other differences. Today, we will discuss some of the main differences between rubber and PVC conveyor belts.

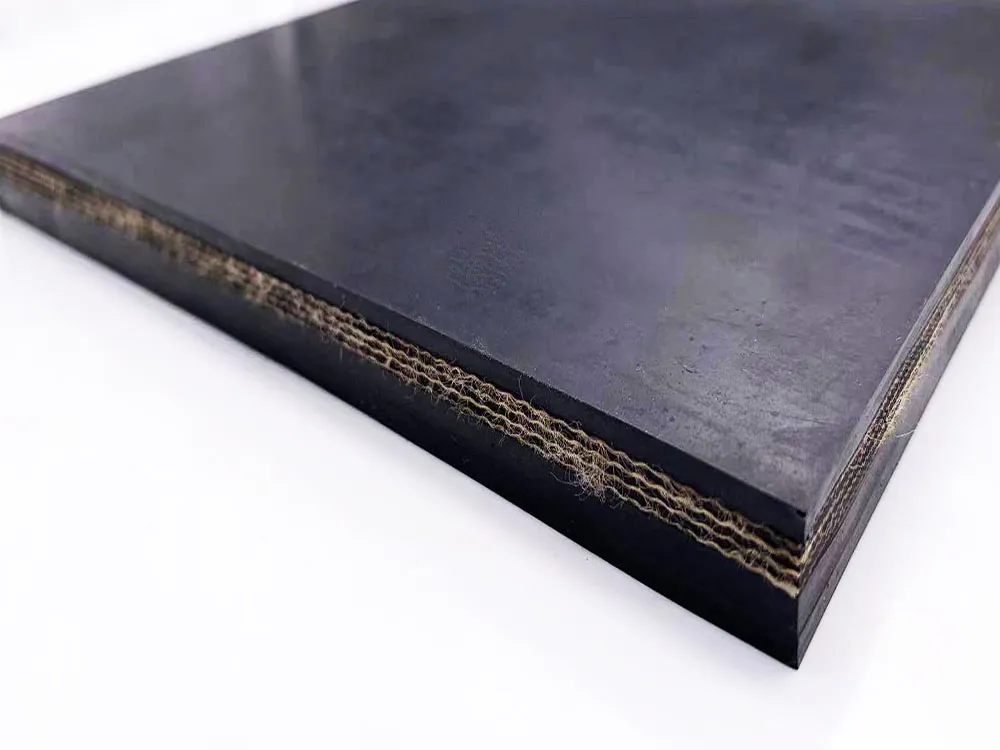

What is a Rubber Conveyor Belt?

As the name implies, a rubber conveyor belt is made of rubber, possibly various types of rubber. Natural, synthetic, or reinforced rubber are popular rubber belting materials. Usually, adding reinforcements to a material makes it last longer and less likely to wear out.

Rubber conveyor belts are naturally robust and flexible. People typically use them to move materials, such as hefty loads and rough materials. However, several types of rubber conveyor belts are used for different purposes.

For example, general-purpose rubber belts are suitable for mining and agriculture. Hot materials like cement or metal parts need heat-resistant rubber belts. Similarly, oil-resistant, flame-resistant, heavy-duty, and chevron rubber belts have different uses.

Benefits of Rubber Conveyor Belts

(1) Rubber belting offers excellent grip compared to PVC belting. This gripping works both against the wheel and the materials. Therefore, your conveyor system ensures more stable movement of the conveyor systems. Also, this strong traction provides a good grip against materials. Thus, this prevents materials from slipping off.

(2) Another crucial benefit of rubber belting is its excellent abrasion resilience. This material works great against material involving wear and tear.

(3) Rubber conveyor belts last long, even in harsh conditions. They can resist cuts, impacts, and heavy loads.

(4) This belting material is naturally very flexible. It bends easily. Therefore, rubber conveyor belts offer the lowest possibility of cracks or breaks.

(5) Rubber conveyor belts can withstand high and low temperatures. Some rubbers are even resistant to fire and chemicals.

(6) Rubber conveyor belts are highly suitable for carrying large, rough, bulky materials. Compared to other types of belting, such as PVC belting, they are highly appropriate for heavy-duty uses.

(7) In general, many different types of rubbers are available. You can also customize the properties based on your application needs. Thus, rubber conveyor belts come in various sizes, thicknesses, and designs.

Limitations of Rubber Conveyor Belts

(1) Rubber belts are comparatively more expensive than PVC belts. There are a few reasons for this. First, rubber requires more processing and manufacturing costs. Second, suitable rubbers are not readily available. Therefore, the type of material and construction you choose determines its final price.

(2) Rubber conveyor belts need extra upkeep and checking compared to other conveyor belts. Over time, these belts may wear out or even form dry rot problems. Still, regular cleaning can eliminate this problem.

(4) Some rubber conveyor belts are suitable for cold surroundings. However, they are not ideal for use in food processing applications. Rubber may absorb moisture and create germs.

What is A PVC Conveyor Belt?

The name “PVC” tells you what the belt is made of: polyvinyl chloride. This is a common type of plastic that is easy to make and used in many market goods. Fabric layers are often added to PVC conveyor belts to strengthen them. This extra layer usually makes the belt stronger and more flexible. The best things about these belts are how heavy and long they last and how well they resist pressure.

PVC conveyor belts come in different types; the exact type typically depends on design and purpose. The most popular types are flat, rough, cleated, food-grade, and antistatic.

These belts are often prevalent in applications where surfaces must be clean and germ-free. But these belts have some flaws that make them less valuable. Most of the time, you can use them for small to medium loads. Because they are made of PVC, these belts are usually easy to clean and keep in good shape. PVC conveyor belts are unsuitable for hot or cold temperatures like rubber belts.

Benefits of PVC Conveyor Belt

(1) PVC conveyor belts are lightweight and flexible. They are also easy to install, transport, and adjust.

(2) This conveyor belt is very resistant to moisture and chemicals. Thus, this belting is ideal for wet or chemical-exposed environments.

(3) PVC conveyor belts offer smooth and hygienic surfaces. They usually don’t build dirt, and they are easy to clean.

(4) These conveyor belts are more affordable than rubber belts. They require less maintenance and last longer for light-duty applications. They are also lightweight and consume less power, reducing system operation costs.

(5) Like rubber conveyor belts, PVC belts are also customizable. You can find various thicknesses, colors, and textures.

Limitations of PVC Conveyor Belt

(1) Although PVC belts are ideal for light to medium load applications, they are not ideal for heavy-duty jobs. For that, you must opt for rubber belts.

(2) These belts are less durable, especially in demanding situations. Also, if your project involves abrasions or high impact, it is better not to opt for PVC belts. Note that PVC conveyor belts become brittle in extreme environments.

(3) PVC belts offer a shorter lifespan than rubber conveyor belts.

Key Differences Between PVC and Rubber Conveyor Belts

| Feature | Rubber Conveyor Belt | PVC Conveyor Belt |

| Material Composition | Natural or synthetic rubber with fabric reinforcements | Polyvinyl chloride (PVC) with fabric reinforcements |

| Durability | High durability, resistant to wear and tear | Moderate durability, best for lighter loads |

| Flexibility | Highly flexible, can handle heavy loads and impact | Less flexible, suitable for light to medium loads |

| Chemical Resistance | Moderate resistance to chemicals and oils | High resistance to chemicals, oils, and moisture |

| Temperature Resistance | Can withstand high and low temperatures | Not ideal for extreme temperatures |

| Surface Texture | Rough or textured for better grip | Smooth for easy cleaning |

| Maintenance | Requires regular maintenance | Easier to clean and maintain |

| Cost | More expensive due to material strength | Generally more affordable |

PVC VS Rubber Conveyor Belt: Which is Better?

Selecting the right conveyor belt is not only necessary for reliability but also for saving costs. As you know, both PVC and rubber conveyor belts are popular in a wide range of applications. However, four key elements typically come into play when you decide between them.

PVC VS Rubber Conveyor Belt: Durability & Strength

Rubber conveyor belts are stronger and very durable. If you are planning to deal with heavy loads and rough environments, choose rubber conveyor belts. They offer excellent resistance to wear, making them ideal for mining, construction, and manufacturing.

PVC belts are lightweight and best for light to medium loads. They work well in clean environments but wear out faster under heavy use.

PVC VS Rubber Conveyor Belt: Flexibility and Applications

PVC conveyor belts are more flexible and easier to install. They are used in food processing, packaging, and logistics.

Conversely, rubber conveyor belts are comparatively heavier and more challenging to install. However, they are ideal for carrying rough materials over long distances.

PVC VS Rubber Conveyor Belt: Chemical and Temperature Resistance

PVC conveyor belts resist moisture, oils, and chemicals, making them perfect for the food and pharmaceutical industries. However, they can not withstand extreme heat or cold.

Conversely, rubber conveyor belts perform better in high-temperature and abrasive environments. They are suitable for factories, quarries, and outdoor applications.

PVC VS Rubber Conveyor Belt: Cost Constraints

PVC conveyor belts are more affordable and need less maintenance. They are a cost-effective option for industries with lighter workloads.

Rubber conveyor belts, on the other hand, have a higher initial cost. However, They offer a longer lifespan in harsh conditions. Because of this, they are ideal for heavy-duty applications.

Conclusion

In the above sections, you have gained much knowledge about rubber conveyor belts vs PVC conveyor belts. Now, it is time for you to choose the right belt. To do this, it is crucial to analyze your project first.

What kind of product does it work with? Is there any possibility of abrasion or wear or tear in it? Does it work with food products? Also, your budget plays an essential role in this selection process. By answering many such questions, you will be successful in choosing the right product.

As you know, both types have advantages and disadvantages. Rubber conveyor belts last longer but require more upkeep. They are also comparatively more expensive than PVC conveyor belts. On the other hand, PVC conveyor belts are much cheaper and easy to maintain. However, they are not as durable as rubber conveyor belts. So, you must understand the fundamental differences between these two materials. This way, you can make the best choice.

If you have any questions, feel free to reach our customer support team. Rentone Belt keeps a very active platform for customer services only. Therefore, you can get quick responses through email, WhatsApp, WeChat or Skype.