Excellence in Quality Assurance and Control

Rentonebelt attaches great importance to quality control and arranges professional staff for every step of quality check. From raw material purchases, all suppliers must pass inspections of quality control. All records are kept in a management system of files. Every bag of our raw materials is tested according to international standards. Only when test data meet relevant standards can raw materials be stored.

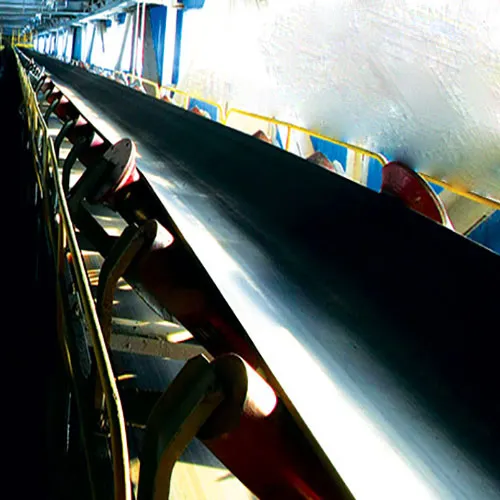

In the process of production, we carefully implement control management. Every step in production adopts strict processing crafts. Self-testing and mutual testing can be carried out in mixing, calendering, forming and vulcanizing, thus ensuring all conveyor belts comply with ISO9001 standards. Meanwhile, our company adopts advanced vulcanizing production lines, mixing production lines and four-wheel calendering lines to ensure the stable quality of products.

In terms of quality inspection, our company is equipped with wear testers, aging testers, ozone resistance testers, tensile strength testers, roller friction testers and run-out testers for conveyor rollers. Before leaving the factory, our conveyor belts are tested for tensile strength, wear resistance and adhesion. The testing results are kept in records, thus making sure of the traceability of products. Only qualified products can leave our factory..